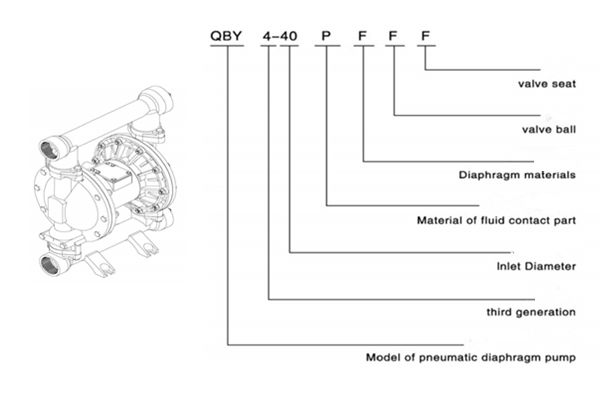

| Item | Description | Material |

| 1 | Model | QBY4 |

| 2 | In/Outlet | 06=1/4” 10=3/8” 15=1/2” 20=3/4” 25=1” 40=1.5” 50=2” 80=3”100=4”125=5" |

| 3 | Center Black | AL-Aluminum PP-Polypropylene SS-Stainless Steel |

| 4 | Pump Body | PP-Polypropylene KV -PVDF PM-POM AL-Aluminum SS-Stainless Steel 304 LL-Stainless Steel 316 AC-Cast Iron TF -PTFE |

| 5 | Diaphragm | TF -PTFE ST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM GE-Geolast PU-Polyurethane |

| 6 | Valve Ball | TF -PTFE ST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM SS-Stainless Steel 304 LL-Stainless Steel 316 CM-Ceramic |

| 7 | Valve Seat | TF -PTFE ST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM SS-Stainless Steel 304 LL-Stainless Steel 316 PP-Polypropylene |

What is corrsion-resistant diaphragm pump?

Air operated diaphragm pump is a new type of conveying machinery, using compressed air as the power source, for all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable, highly toxic liquids, can be exhausted.

The diaphragm pump has 4 materials: plastics, aluminum, stainless steel, and cast iron. The air operated diaphragm pump adopts nitrile rubber, neoprene rubber, fluoro rubber, polytetrafluoroethylene, polyhexaethylene, etc. according to different liquid media to meet the needs of different users. Placed in various special occasions, used to pump various media that cannot be pumped by conventional pumps, and have achieved satisfactory results.

How does an air operated double diaphragm pump work?

Because the diaphragm pump has the above characteristics, the pneumatic diaphragm pump is gradually invading the market of other pumps since its birth and occupying a part of it. For example: air operated diaphragm pumps in the painting and ceramic industries have an absolute dominant position, while in some other industries, such as environmental protection, wastewater treatment, construction, sewage, and fine chemicals are expanding its market share, and other pumps are not available. Alternative status.

The pneumatic diaphragm pump uses compressed gas as the power source, and can be exhausted for all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids. The pneumatic diaphragm pump has four materials: plastic, aluminum alloy, cast iron, and stainless steel. The pneumatic diaphragm pump adopts nitrile rubber, neoprene rubber, fluorine rubber, polytetrafluoroethylene, polyhexaethylene according to different liquid media. To meet the needs of different users. It is installed in various special occasions and used to pump various media that cannot be pumped by conventional pumps, and has achieved satisfactory results.

1. Since gas is used as power, the flow rate is actively adjusted with the change of back pressure (outlet resistance), which is suitable for medium and high viscosity fluids. The operating point of the centrifugal pump is set based on water. If it is used for a fluid with a slightly higher viscosity, it must be equipped with a reducer or a frequency converter, which greatly increases the cost, and the same is true for gear pumps.

2. It is reliable and low-cost to use pneumatic pumps in flammable and explosive environments, such as the transportation of fuel, gunpowder and explosives, because:

– It is impossible to produce sparks after grounding;

– There is no heat generation during work, and the machine will not overheat;

– The fluid will not overheat, because the pneumatic diaphragm pump has the least agitation to the fluid.

3. In the poor center of the construction site, such as construction site, industrial and mining wastewater discharge, due to the large amount of impurities in the sewage and the complex composition, the pipeline is easy to be blocked, which creates an environment with excessive load on the electric pump, and the motor is easily damaged by heat. The pneumatic diaphragm pump can pass particles and has an adjustable flow rate, and will automatically stop when the pipeline is blocked.

4. In addition, the pneumatic diaphragm pump is small in size, easy to move, does not require foundation, has a small footprint, and is easy and economical to install. Can be used as a mobile material delivery pump.

5. In the treatment of hazardous and corrosive materials, the diaphragm pump can completely isolate the materials from the outside world.

6. Or in some experiments, ensure that no impurities contaminate the raw materials.

7. It can be used to transport fluids with relatively unstable chemical properties, such as photosensitive materials, flocculants, etc. This is because the shear force of the diaphragm pump is low and the physical impact on the material is small.

Features and advantages:

1.Light weight,Easy installation and maintenance;

2.Performs on -demand in remote locations;

3.Extremely portable for multi -locations;

4.Little air waste and pulsation, high capacity and performance;

5.Can run dry without pump damage;

6.No air lubrication necessary;

7.The fluid transport is extremely extensive,Can convey acid,alkali,strong organic solvents and other fluid;

8.High temperature resistant, corrosion resistant;

Appication Industry:

Chemical industry: acids, alkalis, solvents, suspended solids, dispersion systems.

Petrochemical industry: heavy oil, grease, mud, sludge, etc.

Coating industry: resins, solvents, colorants, paints, etc.

Daily chemical industry: detergents, shampoos, lotions, emulsions, hand creams, surfactants.

Ceramic industry: mud, porcelain slurry, lime slurry, clay slurry.

Mining industry: coal slurry, magma, mud, mortar, lubricants, etc.

Water treatment: lime slurry, soft sediment, sewage, chemicals, waste water.

Food industry: liquid semi-solid, chocolate, brine, vinegar, syrup, rape oil, soybean oil, honey.

Beverage industry: yeast, syrup, concentrate, gas-liquid mixture, wine, fruit juice, corn syrup, etc.

Pharmaceutical industry: solvents, acids, alkalis, plant extracts, ointments and other pharmaceutical materials.

Paper industry: binders, resins, paints, inks, pigments, hydrogen peroxide, etc.

Electronics industry: solvents, electroplating solutions, cleaning solutions, nitric acid, waste acids, corrosive acids, polishing solutions.

Textile industry: dye chemicals, resins, glues, etc.

Construction industry: cement slurry, ceramic tile binder, rock slurry, ceiling finish, etc.

Automobile industry: polishing emulsion, oil, coolant, automobile primer, oil emulsion, varnish, varnish additives, degreasing liquid, paint, etc.

Furniture industry: adhesives, varnishes, dispersion systems, solvents, colorants, white wood glue, epoxy resins, starch adhesives.

Metallurgy, casting and dyeing industry: metal slurry, hydroxide and carbonized slurry, dust washing slurry, etc